Glass-fused-to-steel tanks are currently one of the best choices for landfill leachate treatment. Tanks used for leachate treatment must have excellent resistance to leachate corrosion. Therefore, the steel plates are subjected to high-temperature annealing to eliminate internal stress in the thick steel, followed by surface pretreatment such as sandblasting. Through mechanical enamel spraying, the enamel coating is applied to the steel surface. After drying and firing, the enamel layer bonds firmly with the steel plate, forming a coating with outstanding resistance to leachate corrosion.

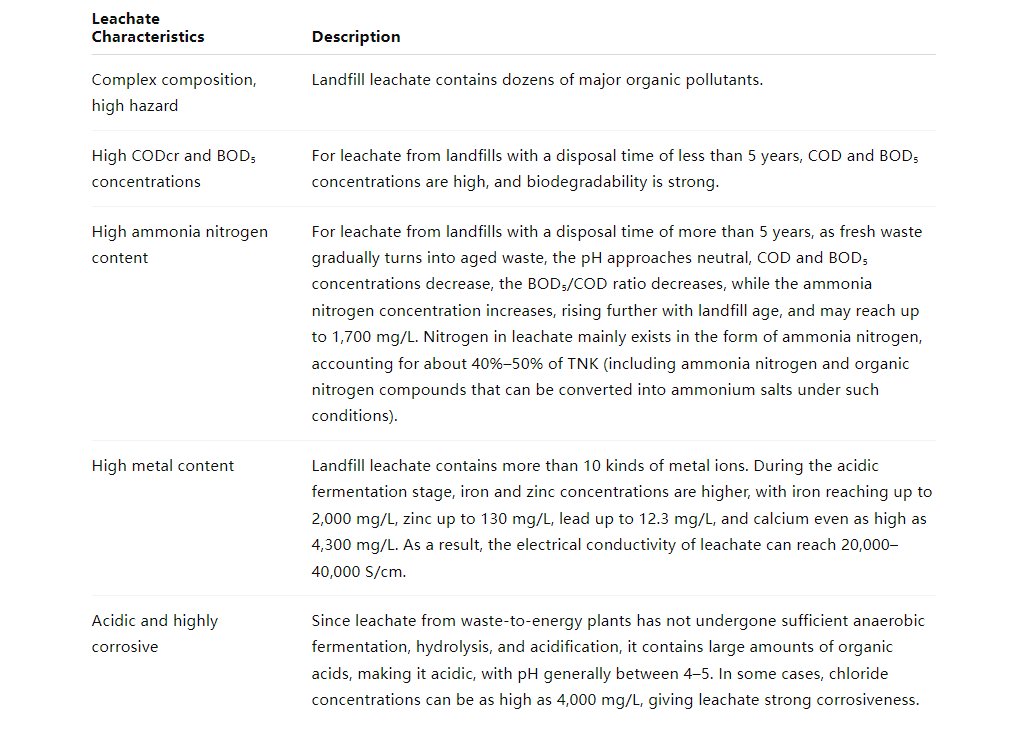

The treatment of landfill leachate has always been a challenging issue in landfill design and operation management. Leachate mainly originates from rainfall and the moisture contained in the waste itself; it is the liquid generated as a result of gravity-driven flow within the landfill. During this flow process, various influencing factors—including physical, chemical, and biological factors—affect the characteristics of the leachate, resulting in a wide range of variations in its properties.

Leachate from municipal solid waste landfills is a type of highly concentrated organic wastewater with a complex composition. Generally, its pH ranges from 4 to 9, the COD (Chemical Oxygen Demand) ranges from 2,000 to 62,000 mg/L, and the BOD₅ (Biochemical Oxygen Demand over five days) ranges from 60 to 45,000 mg/L. The concentrations of heavy metals are roughly consistent with those found in municipal wastewater.

Table 1 Characteristics of Municipal Solid Waste Landfill Leachate

Features of the New Glass-Fused-to-Steel Tank

The new glass-fused-to-steel tank for landfill leachate treatment is made by applying a high-performance, leachate-corrosion-resistant enamel coating onto steel plates, which are then fired and assembled together with hoops, self-locking bolts, sealants, and other accessories. The manufacturing process requires high-temperature annealing of the steel plates to eliminate internal stress, followed by surface pretreatment such as sandblasting. Using computer-controlled mechanical enamel spraying, the corrosion-resistant enamel is evenly applied to the steel surface, then dried at 80–100 °C and fired at 820–900 °C, ensuring a strong bond between the enamel layer and the steel plate.

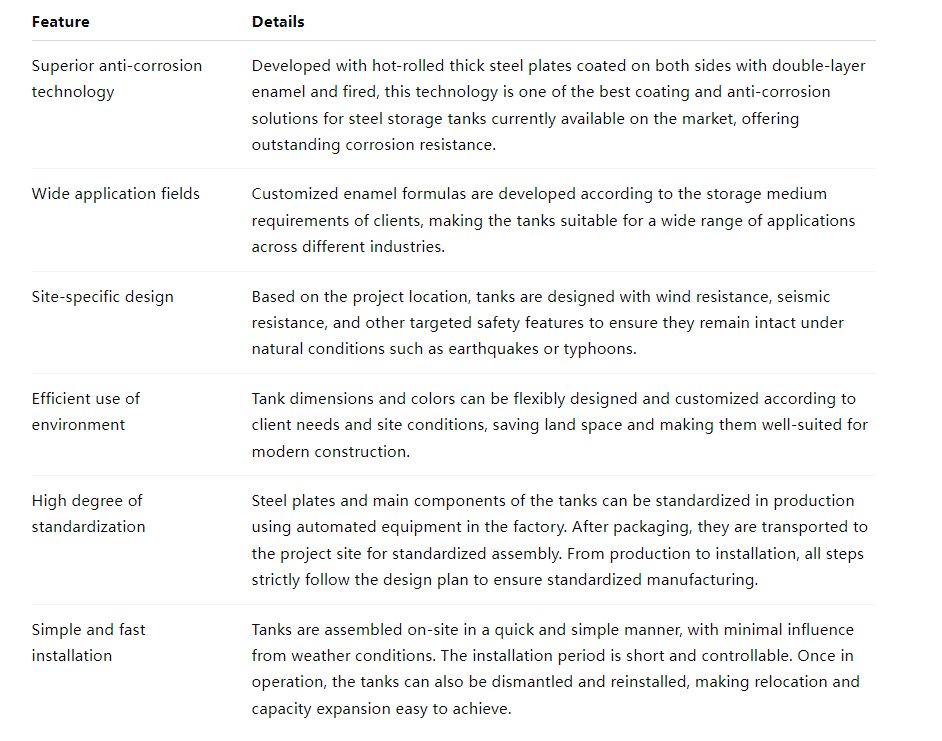

The new enamel-assembled tank for landfill leachate treatment offers the following features:

* Smooth surface and stable quality

* Excellent resistance to acid and alkali corrosion

* High temperature resistance

* Long service life

* Short installation period

* Easy installation and maintenance

* Expandable and relocatable design

* Standardized equipment with a high degree of modularization

* Relatively low cost

Table 2 Features of Glass-Fused-to-Steel Tanks for Landfill Leachate Treatment

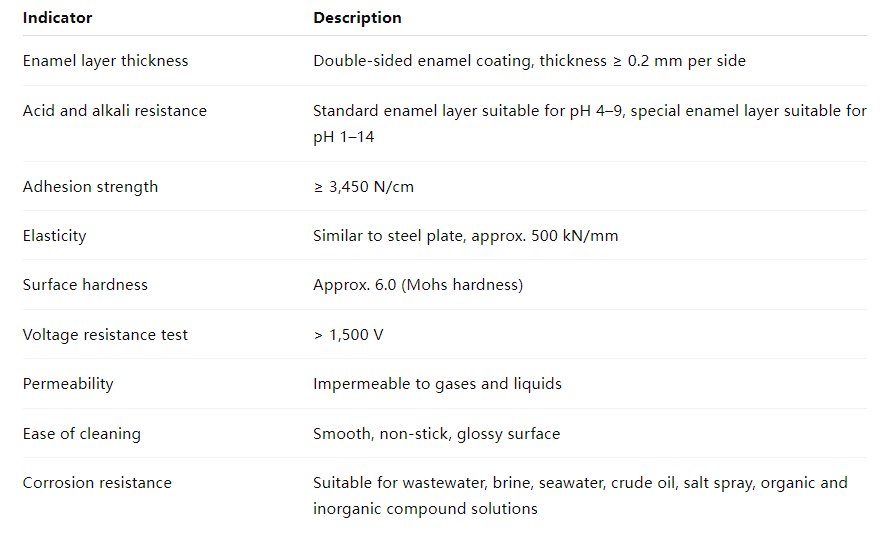

Physical and Chemical Properties of the New Glass-Fused-to-Steel Tank Body

The new glass-fused-to-steel tank for landfill leachate treatment has excellent physical and chemical properties. The specific properties are shown in Table 3

Table 3 Physical and Chemical Property Index of Enamel Materials for Assembled Tank Body

The information comes from the internet and is only for sharing. If you need to delete, please contact us.